ROBOTIC SYSTEMS

Con-Vey’s robotic systems are playing a major role in optimizing production processes.

Many wood product and building material companies struggle to find employees for certain repetitive and monotonous tasks. At Con-Vey, our robotic automation systems provide a solution to your needs.

As an experienced robotic integrator, we provide complete robotics and automation solutions including design, modeling, simulation for movement and time studies, tooling, programming, service, and support. Our robotic automation systems provide safer work environments, save on labor costs, and are proven to increase overall efficiency. That way, you can maintain your competitive advantage and stay ahead of demand.

What can we do with robots? Watch and see.

QUALITY TECH

Our customers have come to expect quality, performance, and durability from everything we produce at Con-Vey. As an ABB Value Provider and partner with Rockwell Automation, we are fully capable of providing an automated system with high-quality parts and technologies, including:

- Robotic Feeders

- Robotic Stackers

- Gantry Systems

- Programmable Logic Controller (PLC) Systems

- Motor Control Centers (MCC)

- Vision Systems

- Servo Controlled Equipment

- Bag Palletizing

- Case Palletizing

- Machine Tending

- Robotic Nailing, Stapling, and Gluing

- Pallet Handling

- Precision Component Handling

- Heavy Load Handling

- Robotic Feeders

- Robotic Stackers

- Gantry Systems

- Programmable Logic Controller (PLC) Systems

- Motor Control Centers (MCC)

- Vision Systems

- Servo Controlled Equipment

- Bag Palletizing

- Case Palletizing

- Machine Tending

- Robotic Nailing, Stapling, and Gluing

- Pallet Handling

- Precision Component Handling

- Heavy Load Handling

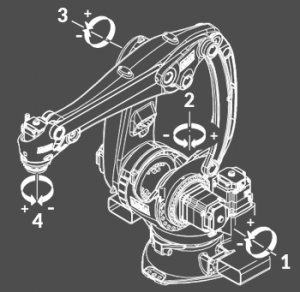

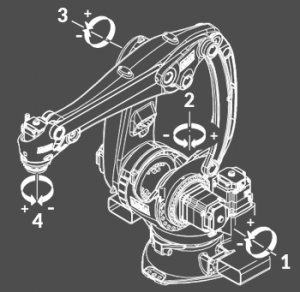

ROBOTS: 4-AXIS & 6-AXIS

The 4-Axis robot arms are ideal for simple pick-and-place applications as well as parts handling or precision assembly.  This style of robot’s primary function is stacking or un-stacking materials. Con-Vey can engineer a custom solution for your application with the flexibility you need to compete in our world’s ever-changing economy. Ranging from 80 lbs to over one-ton of payload capacity, we have the robot that is right for the job.

This style of robot’s primary function is stacking or un-stacking materials. Con-Vey can engineer a custom solution for your application with the flexibility you need to compete in our world’s ever-changing economy. Ranging from 80 lbs to over one-ton of payload capacity, we have the robot that is right for the job.

Six-axis robots offer increased articulation of our Con-Vey designed End Of Arm Tooling (EOAT). As one of the most capable industrial tools in the modern world, a 6-axis robot can work in a wide range of applications. Con-Vey offers a broad selection of robot arms–from the compact to the large capacity–resulting in virtually endless possibilities.

ROBOTS: 4-AXIS & 6-AXIS

The 4-Axis robot arms are ideal for simple pick-and-place applications as well as parts handling or precision assembly.

This style of robot’s primary function is stacking or un-stacking materials. Con-Vey can engineer a custom solution for your application with the flexibility you need to compete in our world’s ever-changing economy. Ranging from 80 lbs to over one-ton of payload capacity, we have the robot that is right for the job.

Six-axis robots offer increased articulation of our Con-Vey designed End Of Arm Tooling (EOAT). As one of the most capable industrial tools in the modern world, a 6-axis robot can work in a wide range of applications. Con-Vey offers a broad selection of robot arms–from the compact to the large capacity–resulting in virtually endless possibilities.

Robots: External Axis

An external axis, or 7th axis, can be added to our robot systems to provide flexibility and increase value. Driven by a servo motor compatible with the robot controller, we can manipulate the position of the robot base. Adding the mobility of an external axis will expand the effective working area and allow the robot to be even more productive.

We also pair a robot with our custom-designed End of Arm Tooling (EOAT), which allows our systems to handle boards, boxes, bags, cases, bottles, kegs, frozen foods, and more. We tailor each EOAT to our customers’ specific product to ensure we’re providing the most efficient and effective handling possible.

Overall, Con-Vey’s robotic systems reduce cost and safety hazards while increasing productivity with a streamlined design by our experienced engineers and programmers. Contact us today for your innovative solution in robotics!

STARTING A NEW PROJECT?

WHAT PEOPLE ARE SAYING

Kyle Freres

Vice President

Freres Lumber Co. Inc.

Alan Plumb

Senior Designer

Smith Monroe Gray Engineers, Inc.

Austen Burk

Senior Plant Engineer

Louisiana Pacific